Mutual Relationship Between Physics, Chemistry and Metallurgy in Welding Processes.

.jpeg)

(GMAW.welding.af.ncs. Author: William M. Plate Jr. Public Domain Licensed) -Wikipedia

Basically welding is the combination of heat and pressure to bond and forge two or more metals together or it can defined as a metal joining process that involves the joining of two metal parts in such a way that the resultant joint is equivalent in composition and characteristics to the metals used.

The science and techniques in welding requires a broad knowledge of chemistry, physics and metallurgy and skills. A good welder is expected to know how the three agents works. Chemistry plays an important but simple role in welding, like the heating and cooling process of the metal, and also the methods used to protect the weld from metal formation oxide is a chemical method. And it is done with the use of protective gases around the puddle.

Physics plays a significant role too in welding, for instance, physics helps the welder to be able to know the various mechanical and chemical properties of materials to be welded, heat affects the toughness and ability of material as well as the ability to bend to any shape the welded wants. A metal can only expand when heat is applied to it and return back when the heat is off.

When the temperature is high it can change the array of structure of a metal which can weaken the metal. A welder should have a knowledge of metallurgy to enable him know the tensile strength and yield.

Welding processes depends on the structure and thickness of the material to be joined or forged. Most times welding is categorize into arc welding and touch welding. We have the gas metal arc welding, submerged arc welding, gas tungsten arc welding, Plasma arc welding and Shielded-metal arc welding. The melting of a material using open flame and welding rod can be referred as touching welding. It is very common in maintenance or repair works. Oxyacetylene welding is an example of touch wedding. There are other types of welding of course, but the ones used here are very common and popular.

Manual metal arc welding is a fusion process using electrical energy to provide the heat necessary to produce melting of the work and electrode. Two forms of electrical energy are used, these are alternating current (a.c) or direct current (d.c). There are three basic types of power source available for energy to be used ,these are the A.C transformer, A. C/d.c transformer rectifier and D.C generator .

With d.c the current flows in one direction only whilst with a.c the current reverses its direction of flow 100 times each second. It requires 1/50 of a second to complete a positive and negative direction of 50 times per second. Therefore with a.c there are no fixed positive or negative poles. With d.c the polarity is fixed and on d.c machines provision is made so that the welding leads can be connected to either the positive (+ve) or negative (-ve) terminals. On some machines the changes of polarity is achieved by means of a switch. Heat energy generated at the welding arc is approximately twice that generated at the negative pole, thus an electrode connected to the positive pole will melt faster than when connected to the negative pole.

The output voltage of the power source referred to as the Open Circuit Voltage (O.C.V) is the voltage of the power with no load i.e, with the machine switched on but no welding taking place. It must be high enough to overcome the resistance between the electrode and the work for an a.c transformer set is generally between 80 and 100 volts and for a motor generator set varies between 40 and 90 volts.

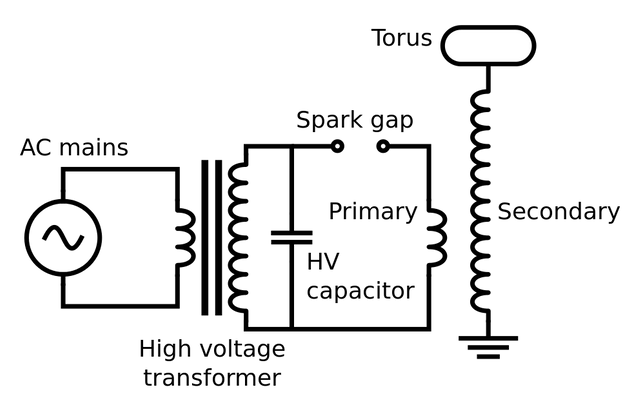

The A.C Transformer

(Tesla coil 4. Author: Omegatron. CC BY-SA 3.0 Licensed) wikicommons

The basic power source delivers only a.c current and consists of a transformers required to reduce the main supply voltage usually in industry, 380 to 400 volts, to a voltage at a much safer level and more suitable for welding i.e 80 to 100 volts. Incorporated in each welding set is a regulating device to control the current out-put of the set. A.C mains supply is readily available and for this reason a.c welding transformers are the most widely used power source in industry. They are generally the most efficient and reliable with low capital cost.

Transformers may be either oil-cooled or air-cooled. The oil cooled models in which the oil acts both, as an insulator and coolant, have no moving pats giving low , operating and maintained costs and are silent in operation. The larger rated air-cooled models use forced air circulation automatically proceeded by a fan motor when the set is switched on. Air-cooled models are consequently lighter in weight making them more portable.

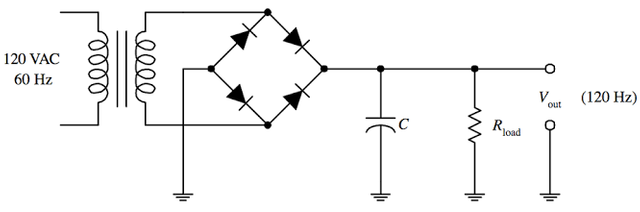

The A.C/D.C Transformer Rectifier

.png)

(ACtoDCpowersupply. Author :JaunJimenez, CC BY-SA 3.0 licensed)- wikicommons

These power sources offer the facility of obtaining either a.c or d.c welding from the same machine. The appearance of the power source is similar to the air cooled a.c transformer sets consisting of a transformer arranged to step down the main voltage to a suitable welding voltage, complete with a current regulation. The a.c output current is then taken through a rectifier unit to convert it to d.c current. Though current flow can be reversed to give electrode positive (+ve) or (-ve) by means of a polarity switch on the power source .

The D.C Generator

(Lancashire - 15kW DC Generator with Hindley High Speed vertical Steam Engine - Birla Industrial & Technological Museum. Author :Biswarup Ganguly. CC BY-SA licensed)wikicommons

The usual type of d.c welding power source is the single operator d.c generator powered by an electric motor or more usually a diesel engine. A generator is specially designed for welding, consisting of an armature rotating in an electric field in which the current is generated and collected at brushes. A polarity switch is provided for changing positive (+ve) to negative (-ve) when a change in polarity is required. Regulations are provided to adjust the open circuit voltage and welding current. Diesel generators are independent of electric power and can be used to advantage on site work and in remote areas where there is no electricity.

Nice

Congratulations! This post has been upvoted from the communal account, @minnowsupport, by Microlead from the Minnow Support Project. It's a witness project run by aggroed, ausbitbank, teamsteem, theprophet0, someguy123, neoxian, followbtcnews, and netuoso. The goal is to help Steemit grow by supporting Minnows. Please find us at the Peace, Abundance, and Liberty Network (PALnet) Discord Channel. It's a completely public and open space to all members of the Steemit community who voluntarily choose to be there.

If you would like to delegate to the Minnow Support Project you can do so by clicking on the following links: 50SP, 100SP, 250SP, 500SP, 1000SP, 5000SP.

Be sure to leave at least 50SP undelegated on your account.